Witherup Fabrication and Erection, Inc. designs, fabricates, erects, and tests welded storage tanks of all sizes (up to 7 million gallons and larger). Our tanks are built to a variety of industry codes including API-650, API-620, AWWA D-100, ASME Section VIII, and NFPA. Materials of construction range from carbon to stainless alloys, and our scope typically includes specified stairs, platforms, coatings, insulation, heaters, and steel containment dikes, and other appurtenances as required.

Witherup offers a range of turnkey services to support any tank project from conception through completion. Witherup’s in-house engineering and fabrication facility enables the level of support needed for the highly effective and efficient field operations, which Witherup is noted for. Witherup also provides tank repair and modification services and shop fabricated tanks and ASME pressure vessels.

Witherup is fully committed to safety. Our personnel have received extensive training and are fully capable of complying with any customer safety policies, and beyond.

Since 1954 Witherup has been providing customers with outstanding service and quality workmanship. No job is too large or too small for Witherup.

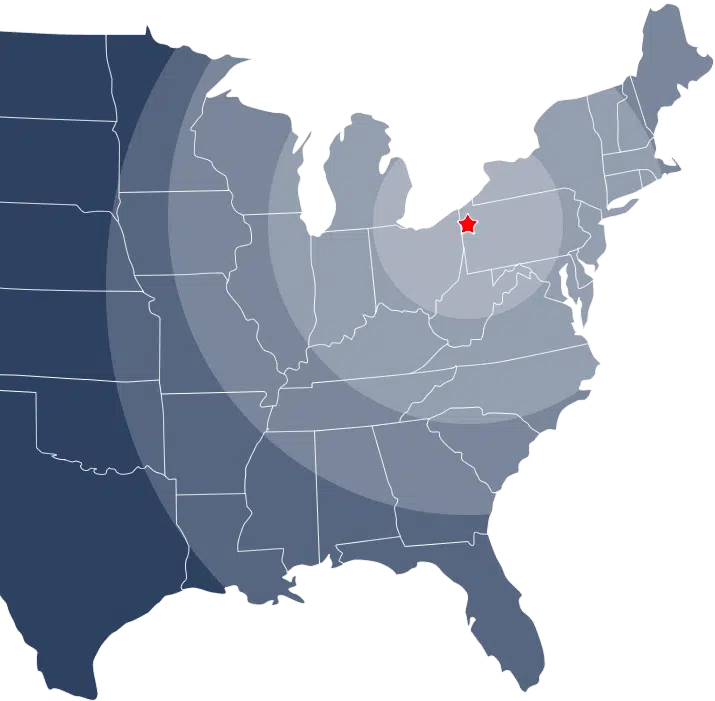

Witherup's service area covers over half of the US Industrial Market and Population

Our Team

Gregory Piercy, President – gpiercy@witherup.com

Jason Woolcock, CPA, Vice President – jwoolcock@witherup.com

Dean Bottorff, Director / Proposals-Subcontracts – dean.bottorff@witherup.com

Brian Kratzer, Project Engineer, – bkratzer@witherup.com

Deriek Shaffer, Project Engineer – dshaffer@witherup.com

Wesley Knight, Safety Manager – wknight@witherup.com

John A. Gieza Jr., Quality Manager (AWS CWI) – jgieza@witherup.com

Ryan Harmon, Material Management – rharmon@witherup.com

Jimmy Ostroske, Shop Superintendent – jimmy2@witherup.com